High-pressure forming systems engineered for ballistic ceramic protection plates, and defense-grade production lines.

Elmali develops hydraulic presses specifically designed for ballistic ceramic powder forming, protective plate shaping, and high-strength material processing. These systems deliver the extreme pressure, temperature control, and precision required for defense and security applications.

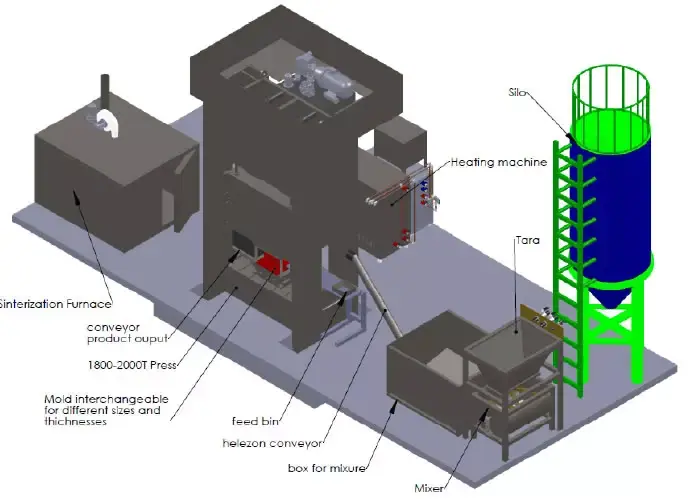

Elmali provides advanced machinery designed for producing high-performance protective plates made from ceramic powders. Its comprehensive production systems feature presses, molds, mixers, furnaces, and other precision-engineered components that enable a streamlined, accurate, and efficient manufacturing process.

A high-pressure hydraulic press engineered for forming ballistic ceramic plates. Designed for ceramic powder materials with precise temperature and pressure regulation.

Designed for defense-grade applications requiring extreme forming forces, multi-stage pressing, and advanced process monitoring.

Our customers craft panels with both single and multi-curved geometries, leveraging advanced thermal processing technologies. By using our precision-engineered presses, they achieve enhanced protective performance, reduced weight, and superior comfort in personal protection applications.

They also manufacture innovative, lightweight ceramic components that deliver exceptional shielding performance, ensuring seamless integration into high-protection systems. We design and produce shielding solutions in a wide variety of sizes and configurations—each one customized to meet exact performance requirements.

Elmali's state-of-the-art hot-forming presses are meticulously programmed to synchronize the heating and cooling cycles with the specific curing process. This precise temperature control ensures the production of premium-quality ceramic components, characterized by optimal material properties and outstanding processing consistency.