+49 (172)5297810

Request a Quote

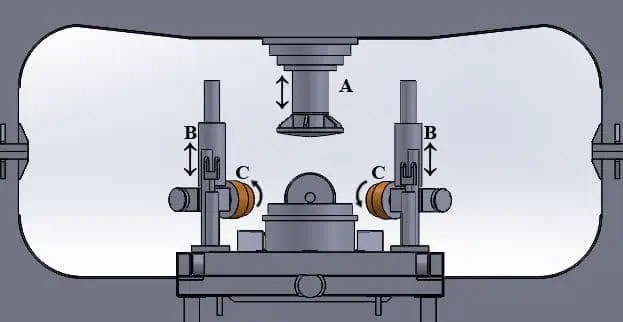

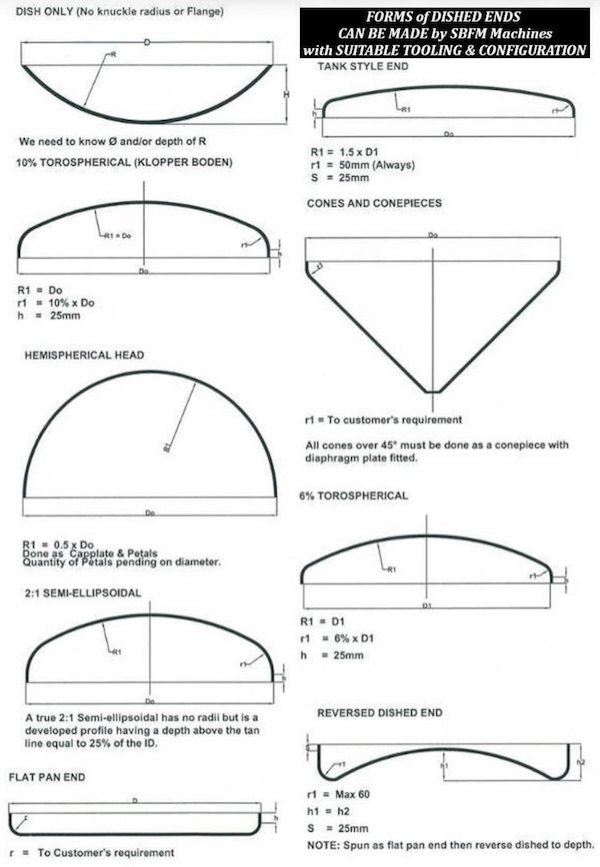

High-precision hydraulic dishing presses engineered for forming and high-force industrial applications.

Our hydraulic dishing presses are designed for demanding industrial environments requiring consistent force, precision control, and long-term reliability. Each system is custom-built to match your production requirements, tooling setup, and automation level.