High-precision hydraulic flanging presses engineered for forming and high-force industrial applications.

Our hydraulic flanging machines are designed for demanding industrial environments requiring consistent force, precision control, and long-term reliability. Each system is custom-built to match your production requirements, tooling setup, and automation level.

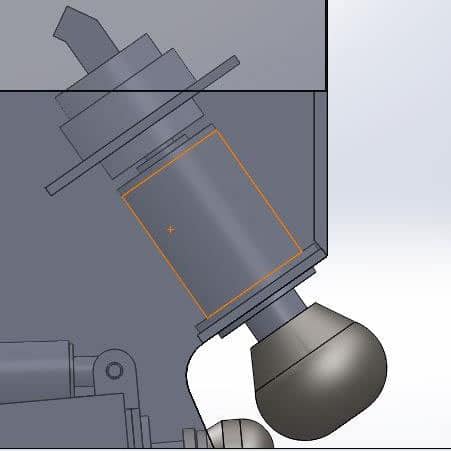

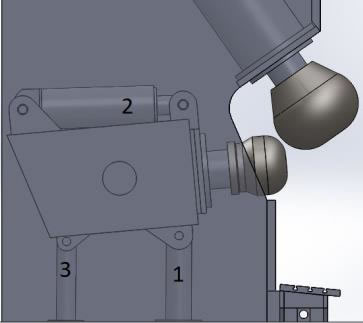

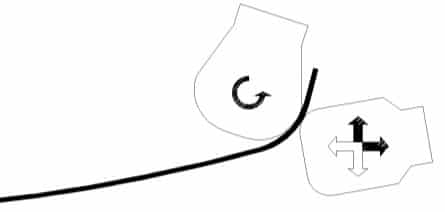

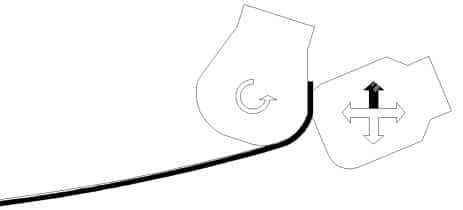

Edge of the dished head is placed between 2 molds which are fixed to shafts that one of them is fixed to top reductor and the other one is idle at down, properly. Spinning process starts when the top shaft is run. After that, hydraulic cylinder with number 3 is moved up. Bending process of edges of dished ends is carried out by linear movement of hydraulic cylinders with number 1 and 2. Then, this process is made two or more times till expected values are obtained in accordance with thickness, depth and diameter measurements. As well, this machine ensures maximum efficiency in the process of making circular form completely of circular part's edge for complete circular bending.

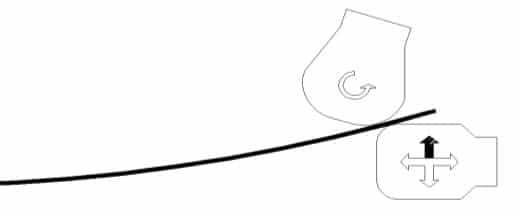

1. First of all, the material is attached to shaft center

2. After that, the material is set for bending with center H and center I buttons

3. C pulley wheels are moved up to support material

4. Adjustment of hydraulic cylinder that Radius A, is set (It is not used in operation unless it is necessery)

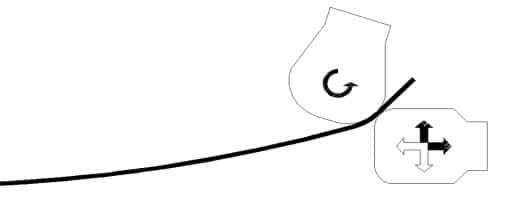

5. Bending process is made properly with the aid of Radius B and Radius F hydraulic cylinders.

6. After bending operation has been completed as MANUALLY, It is changed to AUTO mode and operation is completed as automatically. This is because reducing surface roughness of the flanged part.